39 copper nickel phase diagram

May 27, 2020 · Large-area single-crystal high-index copper and nickel foils with several types of facet are fabricated using mild pre-oxidation of the metal foil surface followed by annealing in … A phase diagram shows the range of existence of phases in materials with more than one component. The binary phase diagram shown for the copper-nickel alloy indicates that these materials can form both liquid and solid solutions over the full range of composition from Cu to Ni. Above 1728 K, the melting point of pure Ni the alloys ar in the ...

Copper–nickel phase diagram including the miscibility gap of the (Cu, Ni) phase: the dashed line denotes the boundary of magnetic transformation The immiscibility of the (Cu, Ni) phase is a ...

Copper nickel phase diagram

A section of the copper-nickel phase diagram is contained here. Both the compositions and the phase amounts of each constituent will be determined at point B. The determination of phase compositions in a single phase, is just how much of each phase is present at a given temperature. In figure 1 at point A, the alpha region is the only phase ... Journal of Phase Equilibria - OOSar: C.I. Sargent, "The Production of Alloys of Tungsten and of Molybdenum in the Electric Furnace,"J. Am. Chem. Soc., 22(12), 783-791 (1980).(Equi Diagram; Experimental) The silver/nickel phase diagram was calculated by the CALPHAD method, and the melting points of 10, 15, and 20 nm silver nanoparticles were predicted at 930.2, 940.7, and 946.0 °C, respectively. We took advantage of the nickel shell to avoid silver sintering and to confirm the calculated melting ...

Copper nickel phase diagram. Jan 16, 2022 · Highlights of the assay results from the 2021 Summer Program from each area examined are shown here, including samples of 15.4% and 11.5% copper, 5.9% nickel, 1,440 and 1,550 parts per million ... November 18, 2009 - P. Nash, Phase Diagrams of Binary Nickel Alloys, ASM International, Materials Park, OH, USA, 1991 (Review) ... P.R. Subramanian, D.J. Chakrabarti, and D.E. Laughlin, Phase Diagrams of Binary Copper Alloys, ASM International, Materials Park, OH, USA (Review) A good interpretation of a binary phase diagram that is easy to understand and interpret is the Cu-Ni system. This diagram has three different phase regions, ... Ask any question and get an answer from our subject experts in as little as 2 hours.

The age-hardenable copper-nickel-silicon alloys with 1.0 to 4.5% Ni and 0.2 to 0.6% Be are not dealt with here. In European standards, these alloys are assigned to ‘low-alloyed copper alloys’ (see R 13388 and relevant product standards). Figure 1. (DKI A 4049) Cu-Ni equilibrium diagram Copper in Powder Metallurgy. A. Phase Diagrams 1. Iron-Copper System The iron-copper phase diagram, taken from Hansen,3 is presented in Figure 1. Hansen3 also gives a thorough review of the work done on the system up to 1957. A review of more recent work, up to 1963 was done by . Elliott~ The most recent version of the phase diagram Shown is a partial binary phase diagram for the Copper-Nickel system with the alloy Cu-35 wt% Ni at the vertical line. At the point, a, the alloy is a liquid. Upon cooling it passes through the two-phase ( a + L) zone and then solidifies as a single phase substitutional alloy. July 9, 2016 - PROPERTIES REFLECT THE STRUCTURE Ceramics were the first artificial material utilized by mankind. Since the dawn of civilization, polycrystalline non-metallic materials, that now we called ceramics, occupy very important but ever changing place in our life. Ceramic thin films used a very large ...

Jan 10, 2022 · The Phase 2 and 3 pits expand laterally towards the northwest and northeast from the Phase 1 pit, providing mill feed for years 22 to 35, allowing tailings to … In the present work, phase diagram is predicted for nanoparticles considering Copper and Nickel and is compared with the experimental results. Copper and Nickel nanoparticles were procured and were characterized for the particle morphology and size using TEM, FE-SEM and XRD. Phases and Phase Diagrams. Activity I: Phases and . Solid Solution Binary . Alloys. A glass of water has sugar slowly added to it until it saturates and a small amount of sugar is left at the bottom. A small amount of extra sugar is then added to the system and students are asked to predict what will happen to the sugar. Shown below is the Cu-Ni phase diagram (Figure 9.3a) and a vertical line constructed at a composition of 70 wt% Ni-30 wt% Cu. (a) Upon heating from 1300°C, the first liquid phase forms at the temperature at which this vertical line intersects the α-(α + L) phase boundary--i.e., about 1345°C.

Copper-Nickel Phase Diagram Pure copper is a relatively soft (pliable) material with good corrosion resistance, excellent electrical conductivity (>100% IACS) and resistant to low-temperature embrittlement.

Introduction to the Cu-Ni phase diagram relating to the use of the Lever Rule for determining composition and phase weight percentages.

9.9 Is it possible to have a copper-nickel alloy that, at equilibrium, consists of a liquid phase of composition 20 ... Shown below is the Cu-Ni phase diagram (Figure 9.3a) and a vertical line constructed at a composition of 70 wt% Ni-30 wt% Cu. (a) Upon heating from 1300°C, the first liquid phase forms at the temperature at which this ...

EN380 Homework #6 Solution 1.The binary (two-component) phase diagram for copper-nickel alloys is shown below. A Cu - Ni alloy contains 30 wt. % Cu at a temperature of 1350 C. Find the following: (a)melting point for pure copper.1084 C (b)melting point for pure nickel.1455 C (c)wt. % Niin the (entire) binary alloy.70% Ni

Jan 30, 2020 · Here the authors deploy Ni single atom-decorated carbon membranes as integrated gas diffusion electrodes to construct an extremely stable three-phase interface for CO2 electroreduction, producing ...

Feb 21, 2016 · Monel is a nickel alloy compromised of mostly nickel (~65%) and copper with other strengthening elements like iron. Monel is stronger than pure nickel and is considered a "single-phase alloy" due to the compatibility of nickel and copper.

The alloy is now fully solid and little diffusion can take place. The grains are uniformly composed of 60% nickel. The grains have a uniform composition because they were cooled slowly. What would happen if cooling occurred rapidly? 'Simple' phase diagrams like this occur when the metal atoms ...

This video explains binary phase diagrams, specifically the Cu-Ni System. For further studies: visit https://www.doitpoms.ac.uk/tlplib/phase-diagrams/printal...

The density of copper (8.93 kg/dm 3 at 20 °C) varies only slightly with increasing nickel content (density of nickel at 20 °C = 8.9 kg/dm 3) and is 8.9 kg/dm3 for all Cu-Ni alloys specified in DIN 17 664. This aspect can also be seen in Table 7 with the physical properties of the Cu-Ni resistance alloys to DIN 17 471.

Source: ASM Alloy Phase Diagrams Center, 2007; data from Okamoto M., The Investigation of the Equilibrium State of the Ternary Whole System Copper-Nickel-Silicon.III. On the Heterogeneous Equilibrium relating to Liquid of the Ternary Whole System Copper-Nickel-Silicon, Nippon Kinzoku Gakkaishi, Vol.

A copper-nickel alloy (solid solution) of composition 60 wt% Ni-40 wt% Cu is slowly heated from a temperature of 1000 C (assume equilibrium conditions). ... By using the phase diagram of a ...

Pb-Sn Phase Diagram Liquidus Solidus Solidus Solidus Solvus Solvus 28. 28 Solidification of Eutectic Mixtures • Mixtures of some metals, such as copper & nickel, are completely soluble in both liquid and solid states for all concentrations of both metals.

The Cu-Ni phase diagram [ 2007Tur] depicts a continuous fcc solid solution between Cu and Ni. The solid solution breaks into Cu-rich and Ni-rich fcc phases at low temperatures. The Fe-Ni phase diagram [ 1991Swa] is characterized by a very narrow solidification range, with a peritectic reaction between (δFe) and liquid yielding (γFe).

S.M. Schwarz et al., “Effects of Diffusion Induced Recrystallization on Volume Diffusion in the Copper-Nickel System,” Acta Mater., 51(10) (2003), 2765–2776.CrossRefGoogle Scholar ... EA. Feest, R.D. Doherty, “The Cu-M Equilibrium Phase Diagram,” J. Inst.

DoITPoMS Micrograph Library Phase Diagram for Cu-Ni. Micrograph Library Browse the libraryAdvanced searchSystemsCompositionsTechniquesKeywordsPhase diagrams.

the phase diagram usually has the general appearance of that in the copper-nickel system shown in Fig. 4.4. Temperature is plotted along the ordinate axis, and the alloy composition is shown on the abscissa axis. The com-position ranges from 0 wt% Ni (100 wt% Cu) on the extreme left to 100 wt% Ni (0 wt% Cu) on the extreme right.

57 Phase Diagram of the Nickel-Bismuth System 58 Phase Diagram of the Copper-Zinc System 59 Phase Diagram of the Copper-Aluminum System 60 Phase Diagram of the Copper-Germanium System 61 Phase Diagram of the Copper-Antimony System 62 Phase Diagram of the Copper-Tin System 63 Additional IV Curves of Solar Cells With Copper Contacts

Abstract. This article is a compilation of ternary alloy phase diagrams for which copper (Cu) is the first-named element in the ternary system. The other elements are Fe, Mn, Ni, Pb, S, Sb, Si, Sn, Ti and Zn. The diagrams are presented with element compositions in weight percent. The article includes 42 phase diagrams (liquidus projection ...

A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 – Binary phase diagrams 6 of 16 11/23/05

The aim of this article is to perform ... phase field model for dendritic solidification of a binary alloy subject to an applied magnetic field in an isothermal environment. Precisely, the numerical stability and error analysis of finite element based approximation scheme are performed. The particular example of a Nickel-Copper (Ni-Cu) binary ...

A common white gold formulation consists of 90% wt. gold and 10% wt. nickel. Copper can be added to increase malleability. The strength of gold–nickel–copper alloys is caused by formation of two phases, a gold-rich Au–Cu, and a nickel-rich …

Consider the binary phase diagram for copper- nickel system, as shown. The abscissa ranges from 0 wt% Ni (100 wt% Cu) to 100 wt% Ni (0 wt% Cu). Three different phase regions (or fields) appear in the diagram: anα field, a liquid (L) field, and a two-phase α+ Lfield.

Alloys of copper (Cu) and nickel (Ni) are an example of such a system. The phase diagram for Cu-Ni is shown in Figure 1203.01.02, where the diagram follows the normal presentation, with the ordinate as temperature and the abscissa is composition, plotted in this case as wt% Ni (Note: an abscissa in atomic % is an ...

for the copper-nickel phase diagram (see figure), find the compositions of the liquid and solid phases for a nominal composition of 70% ni and 30% cu at 1371°c (2500°f). 43000 1600 liquid solution liquid solid 1455-6 (2651-f) 2800 1400 liquidus 2800 1260.c (2300-f) 42400 ic temperature, solidus temperature, 1200 42200 2000 solid solution 1083 …

Binary Isomorphous Diagrams • Isomorphous phase diagrams: Only one solid phase forms; the two components in the system display complete solid solubility (example: Cu-Ni system).--Three different phases that exist over the range of temperatures and compositions: Adapted from Fig. 10.2, Callister 6e. Copper-nickel phase diagram

However, as can be seen from the (γ+γ')/γ' phase boundary on the ternary sections of the Ni, Al, Ti phase diagram, the phase is not strictly stoichiometric. There may exist an excess of vacancies on one of the sublattices which leads to deviations from stoichiometry; alternatively, some of the nickel atoms might occupy the Al sites and vice ...

For the copper-nickel phase diagram in Figure 6.2, find the compositions of the liquid and solid phases for a nominal composition of 70% Ni and 30% Cu at 1371°C (2500°F).

Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash

Literature searched through 1997. Dr. Gupta is the Alloy Phase Diagram Program Co-Category Editor for ternary nickel alloys. ... Gupta, K.P. The Cu-Ni-Ti (Copper-Nickel-Titanium) system. JPE 23, 541 (2002). https://doi.org/10.1361/105497102770331299

Mar 31, 2021 · The Cantor high-entropy alloy (HEA) of CrMnFeCoNi is a solid solution with a face-centered cubic structure. While plastic deformation in this alloy is usually dominated by dislocation slip and deformation twinning, our in situ straining transmission electron microscopy (TEM) experiments reveal a crystalline-to-amorphous phase transformation in an ultrafine-grained …

This representation is called a phase diagram. The phase diagrams of some binary systems relevant to bronze show the behavior of alloying elements that typically results in one of the three cases mentioned previously. The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2).

September 1, 2007 - Download scientific diagram | Copper–nickel phase diagram including the miscibility gap of the (Cu, Ni) phase: the dashed line denotes the boundary of magnetic transformation from publication: Phase equilibria and thermodynamics of binary copper systems with 3 d -metals.

Phase diagrams represent the relationship between temperature and the composition of phases present at equilibrium · An isomorphous system is one in which the solid has the same structure for all compositions. The phase diagram shown is the diagram for Cu-Ni, which is an isomorphous alloy system

at the left of the diagram where the alloy is in solid solution (phase ), a face centred cubic structure like copper. For the typical alloy CuBe1.9 (1.8 to 2% of beryllium) the alloy is in the phase between 720°C and 860°C. For industrial purposes the solution heat treatment is done between 750° and 800°C. By rapidly cooling the

Answer to The copper-nickel phase diagram. Copper and nickel

Last update: Friday, June 1, 2012 4:40:43 PM · To the Ion Scattering and Nanophysics Laboratory in the Department of Physics and Astronomy at Western

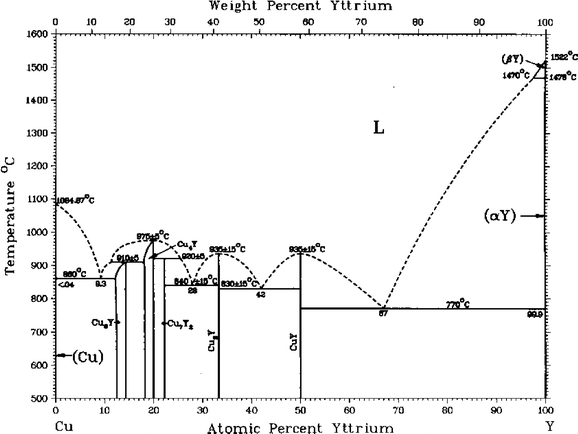

Yttrium barium copper oxide (YBCO) is a family of crystalline chemical compounds, famous for displaying high-temperature superconductivity.It includes the first material ever discovered to become superconducting above the boiling point of liquid nitrogen (77 K) at about 92 K.Many YBCO compounds have the general formula Y Ba 2 Cu 3 O 7−x (also known as Y123), …

The silver/nickel phase diagram was calculated by the CALPHAD method, and the melting points of 10, 15, and 20 nm silver nanoparticles were predicted at 930.2, 940.7, and 946.0 °C, respectively. We took advantage of the nickel shell to avoid silver sintering and to confirm the calculated melting ...

Journal of Phase Equilibria - OOSar: C.I. Sargent, "The Production of Alloys of Tungsten and of Molybdenum in the Electric Furnace,"J. Am. Chem. Soc., 22(12), 783-791 (1980).(Equi Diagram; Experimental)

0 Response to "39 copper nickel phase diagram"

Post a Comment